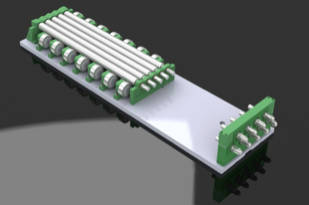

B&D has over 100 years of collective engineering design experience. From equipment repairs, rebuilds, reverse engineering, new equipment design, etc., our highly qualified engineering staff can assist you in all of your project needs. B&D utilizes 2D and 3D modeling software to streamline our ideas to create high quality, economical, robust equipment and weldment designs. We work with your plant supervisors, engineers, support staff, etc., to identify existing equipment issues that you are experiencing and effectively come up with solutions to your problems.

In addition to our ACAD, Solidworks and Inventor software platforms, B&D also operates MasterCAM software for CNC Programming and ProNest software for Plasma Burning of complex plate shapes.

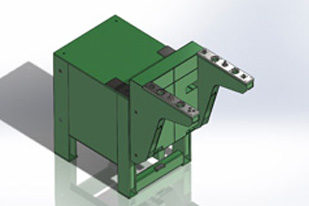

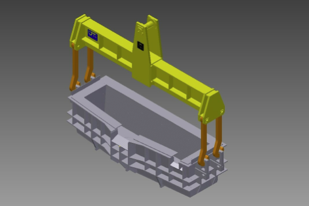

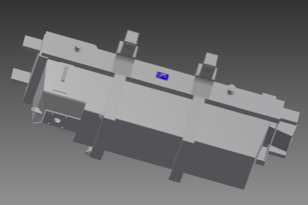

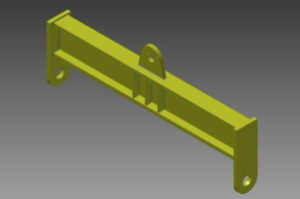

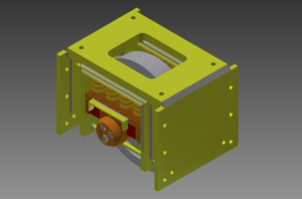

We have worked with customers at steel mills on major redesigns and completely new ideas to improve their process, including oscillating side dams and sticker boxes. The oscillating side dams were a major redesign to an existing piece in the castrip process of making steel, where B&D had to design a way to “shake” the piece next to the pool of steel to prevent the steel from cooling and creating hard lumps. The sticker box functions as a sort of brake/guide for steel, and after working on it made several small redesigns to allow for easier tear down & maintenance at the mill.